Welcome Dongguan Marali Reducer Co., Ltd official website!

Welcome Dongguan Marali Reducer Co., Ltd official website!

On the basis of theoretical calculation and finite element analysis, maraley precision harmonic reducer team, combined with sophisticated inspection system to obtain massive measured data, successfully broke through the non-standard design difficulties of arc-tooth shape by using multi-objective regression optimization method, and developed a breakthrough harmonic reducer.

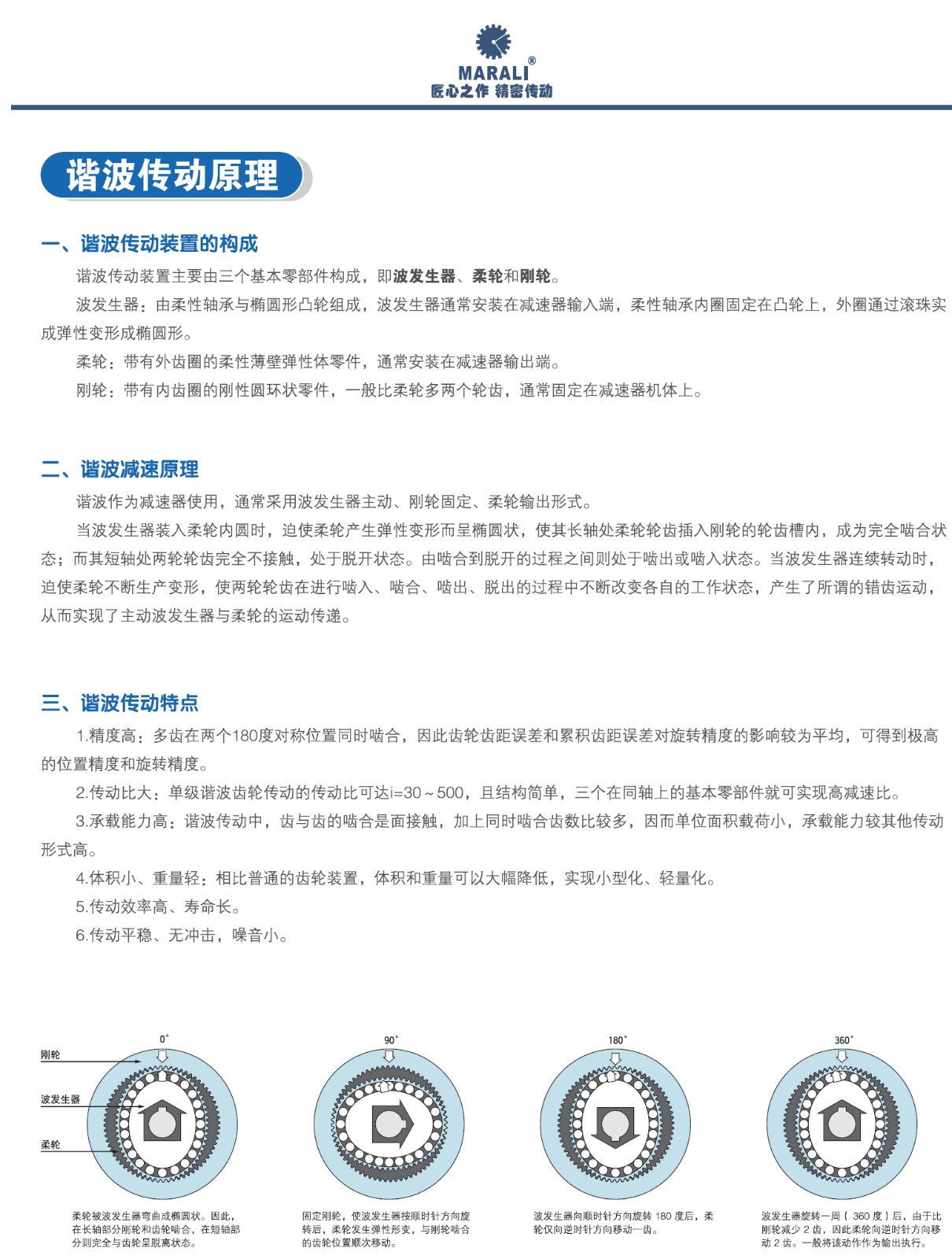

Fine: adopt S shape optimization involute tooth shape structure, meshing more smooth and stable, rigid flexible gear tooth shape processing is to break through the traditional slow wire and hobbing process. With the special process of semi-finishing of hob gear + optical trimming of profile tooth surface precision, multiple teeth are engaged at two 180 degree symmetric positions at the same time, so the effect of tooth spacing error and cumulative tooth spacing error on rotation precision is relatively average, and very high position precision and rotation precision can be obtained.

Long: the flexible wheel material adopts the military steel which is re-dissolved and purified by the customized electroslag, and the thin wall deformation part has achieved the perfect balance of wear resistance and plasticity through repeated spinning process and heat treatment. Steel wheel material adopts ductile iron continuously cast with high spheroidization rate to replace the traditional 40Cr material. The unique self-lubrication of ductile iron is one times higher than the thermal conductivity of steel, which can quickly absorb vibration and reduce wear. Its service life is twice that of the traditional 40Cr steel wheel.

Resistance: soft tooth type processing technology innovation in developed a unique method of deformation after finishing processing, not only can solve the problem of accuracy, but also solve the traditional processing after assembling the problem of uneven deformation of soft steel wheel contact, thus making a good contact with the tooth surface meshing, less stress is more even, friction, high bearing capacity.

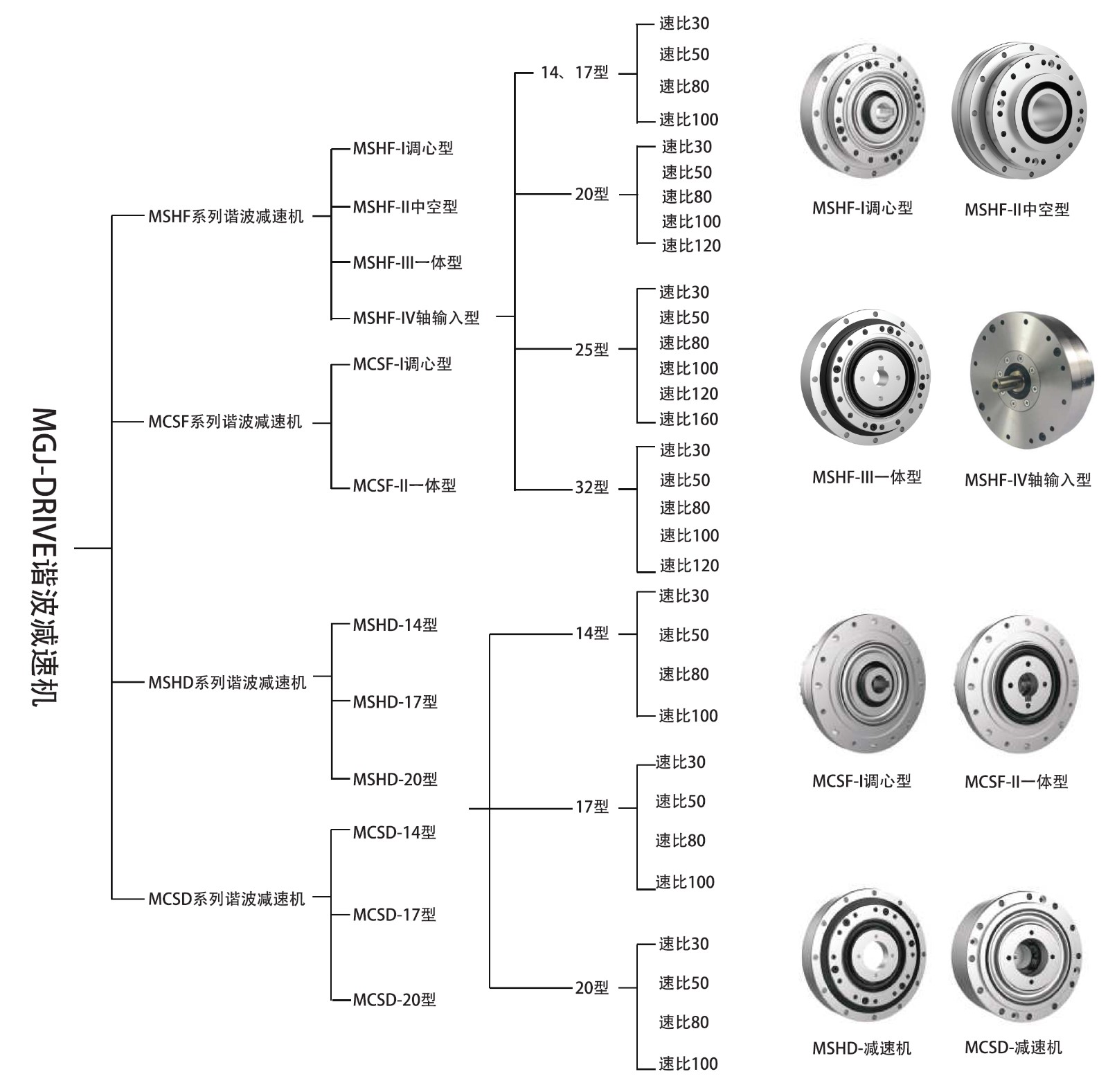

With: large transmission ratio, single harmonic gear transmission ratio up to I = 30 ~ 500, and the structure is simple, three basic parts in the coaxial can achieve a high reduction ratio. In order to meet the needs of the market and users, the CAM flange servo interface specifications of various structures are configured.

Copyright © 2017 Dongguan Marali Reducer Co., Ltd Admin Entrance 粤ICP备17043760号

Powered by:DGyijin